Welcome to GradeSens

PROVIDER OF Digital Solutions in

Predictive Maintenance & POST-Sales Services

for manufacturing, energy and logistics companies

Problem we are solving

For End Users

Financial loss due to technical failure on critical asset because of low/no maintenance

Typical shutdown costs in logistics and energy up to 10M CHF per day

For OEMs (Original Equipment Manufacturers)

Missing revenue due to outdated digital services

Our experience shows that OEMs are missing out on 80% of post-sales revenue from their own customers.

OUR INTEGRATED AND COMPREHENSIVE SOLUTION

We understand our customers’ problems and share our expertise and comprehensive solutions, working on:

Risk-control

Broaden risk coverage on critical assets based on our long term experience.

Digitalisation & AI

Develop and implement specific digital strategy including our hardware and software package.

Distinctive competency

Together with our customers, we define, help and increase their specific digitisation knowledge and value.

our market focus

Industrial manufacturing

We help i.e. Fischer Spindle to develop digital lifecycle services to reinforce their customer relationship.

Energy

We help i.e. Kraftwerke Oberhasli to unlock the potential of their data by developing a digital twin for a 60MW pump-storage

Logistics

We monitor i.e. robots in 3 mail distribution sites of the Swiss Post and Migros to avoid unexpected downtime.

Our large industrial expertise

High Bay Conveyors

Health indicators for the drive train, rail and trolley

Vertical Conveyors

Health indicators for the path homogeneity and belts

Gantry Cranes

Health indicators of hoists, rail surfaces, rollers and path homogeneity

Overhead Crane

Health indicators of the rails path homogeneity

Aggregates

Digital twins for the early detection of failures on inverters, motors, mechanical seals, process equipments

Hydro Turbines and Electric Generators

Digital twins for early detection of failures on turbines, generators

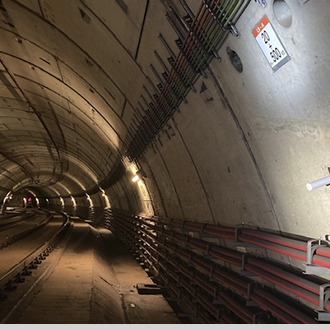

Tunnels

Pattern detection of wall’s vibration

Wind Turbines

Dedicated insight indicators for the main bearings, mast, generators

Ski Lifts

Digital twins for the early detection of failures on inverters, motors, gearbox

Lifts

Insight indicators for guiding issues, inadequate controller parameters and ageing of the driving belts

Companies trust us

Our end-to-end digital suite

Our vast domain knowledge and engineering background allow us to have a comprehensive holistic approach in digitalisation:

1. Smart sensors & Data collection

Our sensors act like our eyes and ears

2. Data consolidation & analysis

Our AI Digital Twin analyzes the data with dedicated codeless algorithms

3. Actionable insights & guidance

Recommendations based on our algorithm results and related KPIs (Key Performance Indicators)

Business Model

Consulting & Pilot project

- Project Analysis

- Hardware / Software

- Consulting / Services

- Customer Results

A.) Monitoring services

- AI Analytics/ Monitoring Solutions based on pilot project

- Annual Maintenance/ licensing update

B.) Licensing to clients

- Perpetual License Agreement & Software Solutions

- Separate consulting & Training Services

- Annual Maintenance / Release Update