Wind

Challenges in life cycle management of wind farms

In Europe, many wind farms are getting older than 15 years and reaching their post Full Agreement Life Cycle. For such wind farms, strategic questions in regards to the optimal life cycle management strategy needs to be properly addressed with options such as repowering, power boosting, parametric insurance, health and credit score for sale and refinancing, continuous assessment of the structural integrity following natural hazards.

Solution for Wind Turbine Generators

- Integrated "all-in-one" platform: Data Acquisition, Data Management, Analytics and Reporting

- Enhancement of the current Dataset with new Data acquired by our wireless Data Acquisition System e.g. for the Monitoring of the Main Bearing and the Mast

- Pre-defined Heath Indicators focused on the Detection of critical Failures on the Main Bearing and Generator

- Pre-defined Health Indicators for the WTG power performance

- Pre-defined Health Indicators for the Structure Health Monitoring of the Tower

Advantages

- Integrated "all-in-one" platform: Data Acquisition, Data Management, Analytics and Reporting

- Enhancement of the current Dataset with new Data acquired by our wireless Data Acquisition System e.g. for the Monitoring of the Main Bearing and the Mast

- Pre-defined Heath Indicators focused on the Detection of critical Failures on the Main Bearing and Generator

- Pre-defined Health Indicators for the WTG power performance

- Pre-defined Health Indicators for the Structure Health Monitoring of the Tower

Typical Health Indicators

- Machine performance - prediction of the expected power output

- Main Bearing - Prediction of the bearing vibration

- Generator - Prediction of the bearings vibration and temperature

- Mast - Prediction of the Health State

Typical examples

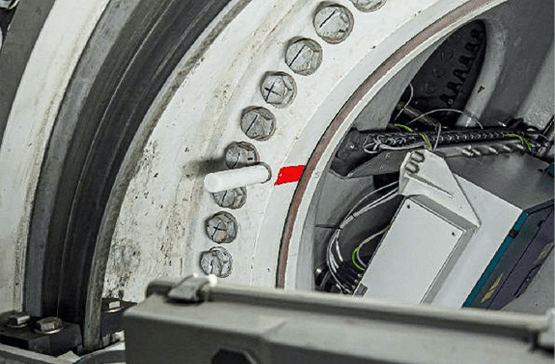

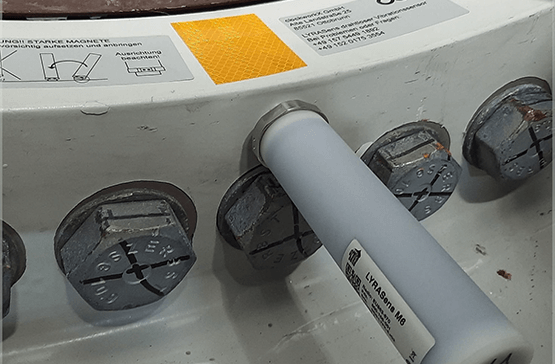

LYRASens wireless sensors mounted on WTG rotating parts