Logistics

Comprehensive AI Monitoring for automated warehouses

Intralogistics is a critical element of the supply chain. Any unplanned interruption of the flow gives rise to heavy costs and stressful situation for the operators.

With the emergence of e-commerce and the ever more rigorous requirements of storage conditions, warehouses are getting always more automated and technically sophisticated. Their maintenance is becoming a core process.

The Monitoring of Automated Warehouses is therefore a solution for operators to get a better grip on their systems.

Solution for logistics

- Integrated "all-in-one" platform: Data Acquisition, Data Management, Analytics and Reporting

- Installation on any type of Logistics Platforms

- Autonomous Data Acquisition without any iInterface with the existing Automation Architecture

- Pre-defined Heath Indicators focused on the Detection of critical Failures

- Integrated Dashboard for the follow-up the Health Indicators

Advantages

- Systemic overview of the health state of the machines

- Fault free operation

- Extension of the risk coverage

- Optimisation of the machine performance

- Maintenance planned with 6-12 months advanced notice

Typical Health Indicators

- Anomalies in the speed profil caused by structure instabilities and inadequate controller parameters

- Anomalies in the transverse direction of the robots cased by clearance in the guiding wheels

- Anomalies in the radial vibration of the guiding wheel axis in the vertical direction cased by degrading wheel quality, unclean or abnormal clearance of rails and wear-outs on the bearings, clamp and gearbox

- Anomalies of the hub's breakdown quality caused by inadequate controller parameters or ageing of the driving belts

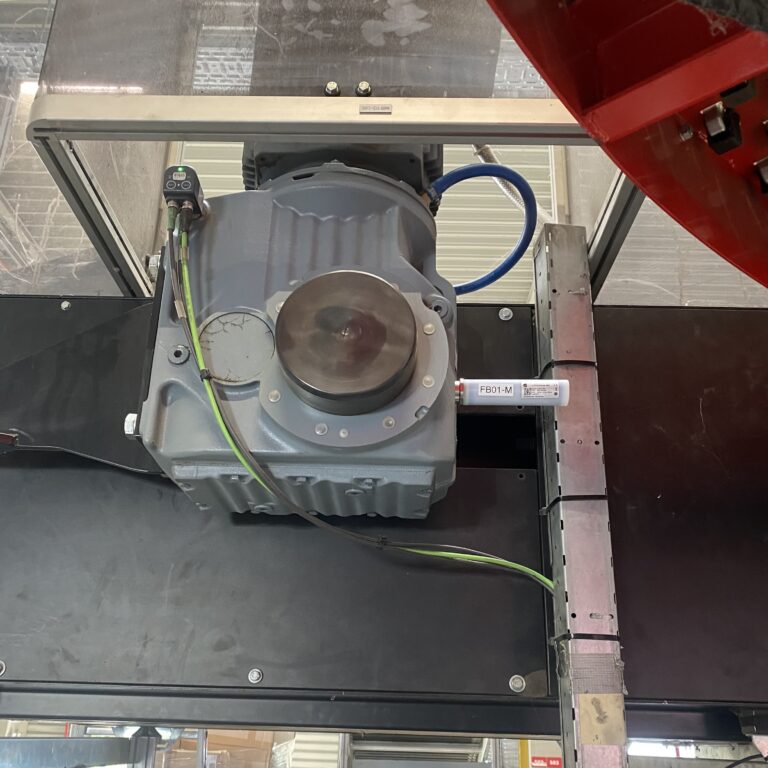

High Bay Conveyors

Health indicators for the drive train, rail and trolley

Vertical Conveyors

Health indicators for the path homogeneity and belts

Gantry Cranes

Health indicators of hoists, rail surfaces, rollers and path homogeneity

Overhead Crane

Health indicators of the rails path homogeneity

Lifts

Insight indicators for doors, winches, breaks

Conveyor belts

Health indicators for the structure and motor vibration