Aggregates

Monitoring of Aggregates

Critical aggregates (system composed by several separate machines) are equipments for which every unplanned downtime causes significant non-production costs. To avoid them, many critical aggregates are today covered by aggressive and costly preventive maintenance plans.

Predictive maintenance is not very widespread because the costs of digitisation are often high. IoT solutions on the market do not cover the monitoring requirements properly, so that they should be monitored with costly cabled Condition Monitoring Systems (CMS).

Data provided by CMS Systems are complex to analyse and requires special skills.

CMS Systems based on classic vibration monitoring are well known since many years for their ability to detect issues on the shaft dynamic and bearings. But they are quite limited to detection other issues e.g on the inverters or on the mechanical seals.

Solution for aggregates

- Integrated "all-in-one" platform: Data Acquisition, Data Management, Analytics and Reporting

- Acquisition of existing SCADA & Cloud Data enhanced when needed with new data Data acquired by our wireless acquisition system

- Wireless technology for the industry: long range, multi-sensors simultaneous acquisition, fast and non intrusive installation

- Open and integrable architecture

Advantages

- Systemic overview of the health state of the machines

- Fault free operation

- Extension of the risk coverage

- Optimisation of the machine performance

- Maintenance planned with 6-12 months advanced notice

Typical Health Indicators

- Machine performance - prediction of the expected power output

- Prediction of the bearing vibration and temperature

- Prediction of inverter temperature

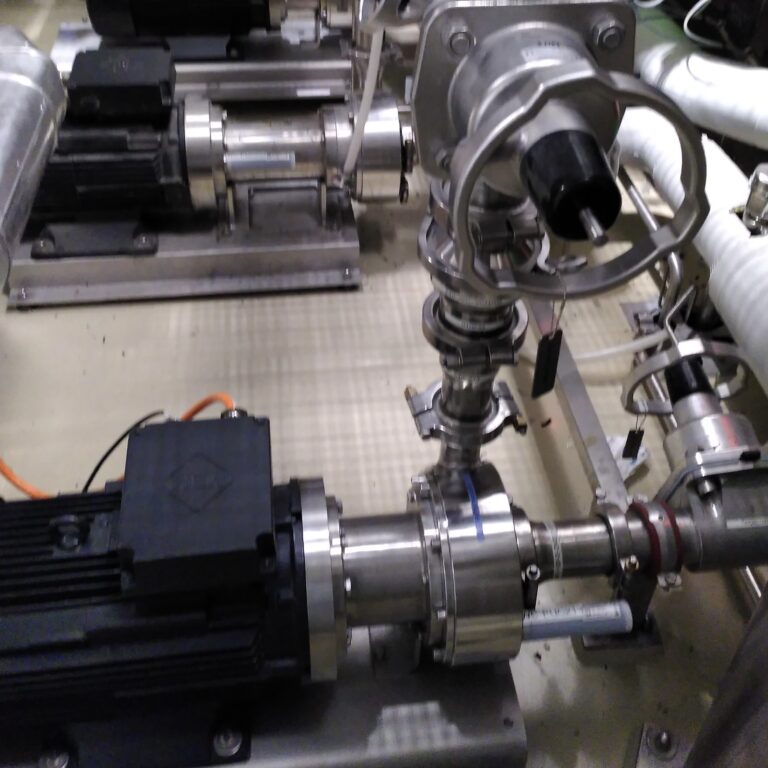

WFI Pumps (pharma)

Detection of water hammer, unbalance on the magnetic coupling, inefficiencies

Pumps

Failure detection on bearings

Ventilators

Failure detection on bearings

Evaporator

Detection of early stage failures on the bearing, mechanical seal, inverter, leakage in the circuit,...